cable size and current rating pdf

Cable size and current rating are critical factors in electrical systems, ensuring safety, efficiency, and reliability. They determine the maximum current a cable can handle without overheating, considering voltage drop and environmental conditions. Proper sizing prevents overheating, reduces energy losses, and ensures optimal performance. This guide provides essential insights into selecting the right cable size and understanding current ratings for various applications.

1.1 Understanding the Importance of Cable Size and Current Rating

Cable size and current rating are vital for ensuring electrical systems operate safely and efficiently. They determine the maximum current a cable can handle without overheating, considering voltage drop and environmental conditions. Proper sizing prevents overheating, reduces energy losses, and ensures optimal performance, making it essential for reliable power distribution and system longevity.

1.2 Overview of Cable Size and Current Rating Charts

Cable size and current rating charts provide essential data for selecting appropriate cables. They detail cross-sectional areas, current ratings, and voltage drop considerations, helping ensure safe and efficient installations. These charts often reference standards like DIN VDE, offering a quick reference for engineers to determine the right cable for specific applications and conditions.

Factors Influencing Cable Size and Current Rating

Power and voltage requirements, current carrying capacity, voltage drop, and environmental conditions like temperature and installation methods significantly influence cable size and current rating selections, ensuring safe and efficient operation.

2.1 Power and Voltage Requirements

Power and voltage requirements directly influence cable size and current rating. Higher power demands necessitate larger cables to handle increased current, calculated using P=V*I. Ensuring the cable can manage the required current without overheating is critical for safe and efficient operation, as specified in cable size and current rating charts.

2.2 Current Carrying Capacity and Voltage Drop

Current carrying capacity determines the maximum amps a cable can handle without overheating, while voltage drop affects power delivery efficiency. Exceeding the 4% voltage drop threshold may require upsizing the cable. Proper sizing ensures safe operation and minimizes energy losses, as outlined in cable size and current rating charts.

2.3 Ambient Temperature and Environmental Conditions

Ambient temperature significantly impacts cable current ratings, as higher temperatures reduce maximum allowable current. Environmental factors like humidity, air circulation, and installation methods (e.g., underground or aerial) also influence cable sizing. Adherence to temperature and environmental correction factors ensures safe and efficient cable operation, as detailed in cable size and current rating charts.

Cable Size and Current Rating Calculation Methods

Calculate cable size using formulas, charts, and software tools. Consider voltage drop, power requirements, and environmental factors. Apply reduction factors for multiple conductors and ambient temperature conditions for accurate sizing.

3.1 Using Wire Size Charts and Tables

Wire size charts and tables provide a quick reference for determining appropriate cable sizes based on current ratings, voltage drop, and operating temperatures. These charts, often based on standards like DIN VDE, list cross-sectional areas, diameters, and maximum permissible currents. By matching the required current to the chart, users can select the correct cable size efficiently, ensuring safe and reliable electrical connections while minimizing voltage drop and heat generation.

3.2 Calculating Voltage Drop Along the Circuit

Voltage drop calculations ensure cables operate within acceptable limits, preventing energy losses and equipment malfunction. Using formulas like E = I × R × L, where E is voltage drop, I is current, R is resistance, and L is cable length, engineers can determine if a cable size is suitable. This step ensures efficient power delivery and system reliability.

3;3 Applying Reduction Factors for Multiple Conductors

Reduction factors are applied when multiple conductors are bundled, as they reduce the current rating due to shared heat dissipation. These factors, found in standards like DIN VDE, ensure cables operate within safe temperature limits. Neglecting them can lead to overheating and system failure, emphasizing the need for accurate application in designs.

Cable Size and Current Rating Charts

Cable size and current rating charts provide detailed cross-sectional areas, diameters, and current ratings for single and three-phase systems. They include voltage drop considerations and compliance with standards like DIN VDE.

4.1 Cross-Sectional Area and Diameter of Conductors

Cross-sectional area and diameter are key factors in determining a conductor’s current-carrying capacity. Charts provide precise measurements, ensuring cables meet power requirements without excessive voltage drop or overheating. This data is crucial for selecting the right conductor size for safe and efficient electrical installations.

4.2 Current Rating for Single and Three-Phase Systems

Current ratings differ between single-phase and three-phase systems due to phase differences and system requirements. Three-phase systems typically handle higher currents, requiring adjusted cable sizing. Charts provide specific ratings for each configuration, ensuring safe and efficient power distribution while adhering to international standards like IEC for accurate calculations.

4.3 Voltage Drop Considerations in Cable Selection

Voltage drop is a critical factor in cable selection, impacting system efficiency and safety. It depends on cable size, length, load current, and power factor. Excessive voltage drop can lead to overheating, reduced performance, and potential system failures. Using charts and calculations helps determine the appropriate cable size to stay within allowable limits, ensuring reliable operation and compliance with standards.

Voltage Drop and Its Impact on Cable Size

Voltage drop significantly impacts cable size selection, ensuring efficient and safe electrical installations by preventing overheating, reducing energy losses, and maintaining optimal power delivery.

5.1 Understanding Voltage Drop in Wiring Circuits

Voltage drop occurs when electrical current flows through a cable, causing energy loss as heat. It depends on cable size, material, and circuit length. Excessive drop can reduce system efficiency and damage equipment. Understanding voltage drop is crucial for proper cable sizing to ensure reliable and efficient power delivery in electrical systems.

5.2 Calculating Voltage Drop for Different Cable Sizes

Voltage drop is calculated using the formula: ( VD = rac{I imes R imes L}{1000} ), where ( I ) is current, ( R ) is cable resistance, and ( L ) is length in meters. Larger cables have lower resistance, reducing voltage drop. Always consult cable size charts for specific scenarios to ensure accurate calculations and efficient power delivery.

5.3 Adjusting Cable Size to Minimize Voltage Drop

To minimize voltage drop, calculate the required cable size using voltage drop formulas and charts. If the calculated drop exceeds acceptable limits, upsize the cable. Refer to cable size and current rating PDF guides for precise values. Iterating on cable size ensures optimal performance and compliance with system requirements.

Standards and Regulations for Cable Sizing

Standards like DIN VDE, IEC, and local electrical codes provide guidelines for cable sizing, ensuring safety, efficiency, and compliance. These regulations outline current ratings, voltage drop limits, and installation practices.

6.1 DIN VDE Standards for Cable Sizing

DIN VDE standards provide detailed guidelines for cable sizing, focusing on current ratings, voltage drop, and safety. These standards ensure cables operate within safe temperature limits and meet specific installation requirements, particularly in industrial and commercial settings.

6.2 IEC and Other International Standards

IEC standards provide global guidelines for cable sizing, current ratings, and voltage drop calculations. They ensure safety, efficiency, and compatibility across international markets. These standards cover conductor materials, ambient conditions, and installation practices, offering a harmonized approach for cable selection and compliance in diverse industrial and commercial applications worldwide.

6.3 Compliance with Local Electrical Codes

Adhering to local electrical codes is essential for legal and safety compliance. These codes often incorporate international standards like IEC but tailor requirements to regional conditions. Compliance ensures installations meet safety, efficiency, and legal standards, avoiding potential penalties and ensuring reliable electrical systems tailored to local environmental and regulatory demands.

Safety Considerations in Cable Size Selection

Ensuring cables operate within safe current limits prevents overheating and fire hazards, while proper insulation and short circuit protection enhance overall system safety and reliability.

7.1 Maximum Permissible Current for Safe Operation

The maximum permissible current ensures cables operate safely without overheating. It is determined by conductor material, insulation type, and ambient temperature, with reduction factors applied for multiple conductors. Always reference standards like DIN VDE to ensure compliance and prevent fire hazards, guaranteeing reliable and long-lasting electrical system performance.

7.2 Short Circuit Current and Temperature Rise

Short circuit currents cause rapid temperature rise in cables, potentially leading to insulation failure. Calculating these parameters ensures cables withstand faults without damage. Standards like DIN VDE provide guidelines to determine maximum allowable short circuit currents and corresponding temperature limits, ensuring safe operation and preventing overheating during fault conditions.

7.3 Insulation and Fire Safety Ratings

Insulation and fire safety ratings are crucial for preventing electrical fires and ensuring cable durability. These ratings determine a cable’s ability to withstand high temperatures and resist fire spread. Materials like cross-linked polyethylene offer enhanced thermal resistance. International standards, such as IEC 60331-21, provide testing and certification guidelines for fire-resistant cables;

Applications of Cable Size and Current Rating

Cable size and current rating are essential in power distribution, industrial automation, and renewable energy systems. Proper sizing ensures efficient energy transfer, safety, and system reliability across applications.

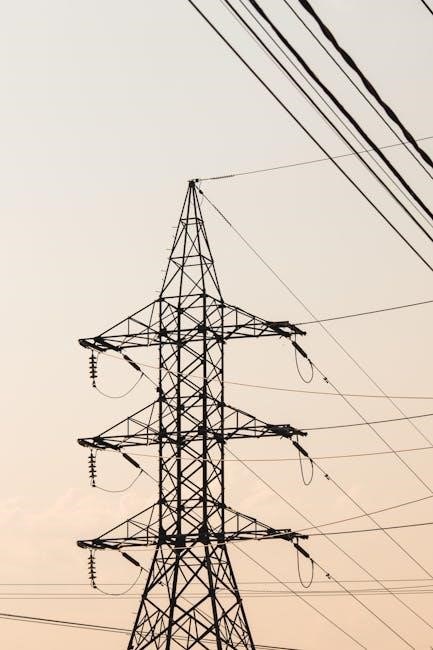

8.1 Power Distribution Systems

In power distribution systems, accurate cable sizing ensures reliable energy delivery. Correct current ratings prevent overheating and voltage drop, maintaining system efficiency. This is crucial for both residential and industrial setups, ensuring consistent power supply and safety. Proper sizing also minimizes energy losses, optimizing overall system performance and longevity.

8.2 Industrial Control and Automation

In industrial control and automation, precise cable sizing and current ratings are essential for reliable signal transmission and power supply. Proper sizing ensures minimal interference, efficient operation, and durability in harsh environments. This maintains system performance, reduces downtime, and enhances overall industrial productivity and safety.

8.3 Renewable Energy Systems (Solar, Wind)

In renewable energy systems, cable size and current rating are crucial for efficient power transfer from solar panels or wind turbines to inverters and grids. Proper sizing ensures minimal voltage drop, maximizing system efficiency and reliability. Durable materials are selected to withstand outdoor conditions, ensuring long-term performance and safety in renewable energy applications.

Environmental Factors Affecting Cable Size

Environmental factors like temperature, humidity, and installation conditions significantly impact cable size selection. High temperatures reduce current-carrying capacity, while corrosive environments require specialized materials. Proper sizing ensures reliability and safety under varying conditions.

9.1 Temperature and Humidity Considerations

Temperature and humidity significantly influence cable sizing and current rating. Higher temperatures reduce a cable’s current-carrying capacity, requiring derating factors to prevent overheating. Humidity can degrade insulation integrity, affecting performance and safety. Environmental corrections ensure cables operate reliably under varying conditions, maintaining efficiency and preventing potential failures. Proper sizing accounts for these factors to ensure optimal performance.

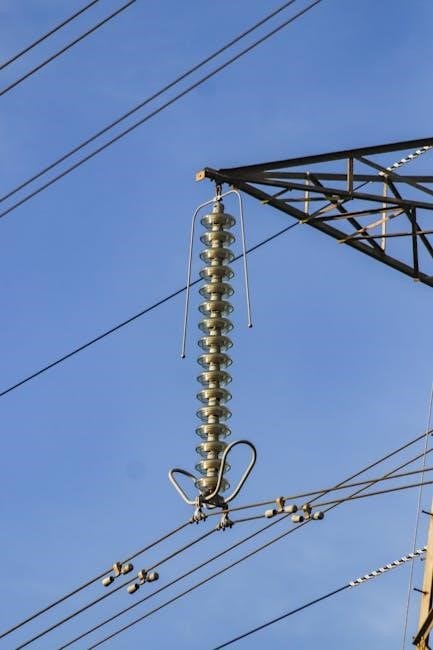

9.2 Cable Installation Methods ( Underground, Aerial)

Installation methods significantly impact cable size and current rating. Underground cables require thicker insulation and protection against moisture and mechanical stress, while aerial cables must withstand wind, weather, and UV exposure. Both methods demand careful consideration of environmental factors to ensure safe and efficient operation, with adjustments made to current ratings as needed.

9.3 Corrosion and Chemical Resistance

Corrosion and chemical resistance are vital for cable longevity, especially in harsh environments. Cables exposed to corrosive substances or moisture must have protective coatings or insulation to prevent degradation. Materials like PVC or PE are often used to enhance resistance, ensuring safe operation and maintaining current-carrying capacity in challenging conditions.

Selecting the Right Cable for Specific Needs

Selecting the right cable involves matching size to load requirements, choosing conductor materials, and considering environmental factors. Consult cable size charts to ensure safety, efficiency, and reliability in installations.

10.1 Matching Cable Size to Load Requirements

Calculating current requirements is essential for selecting the right cable size. Use cable size charts to match the load’s amps and voltage, ensuring minimal voltage drop. Proper sizing prevents overheating, reduces energy losses, and guarantees safe, efficient operation. Always consider environmental factors and compliance with relevant standards for optimal performance and reliability.

10.2 Choosing the Right Conductor Material (Copper, Aluminum)

Copper and aluminum are common conductor materials. Copper offers higher conductivity, durability, and resistance to corrosion, making it ideal for high-current applications. Aluminum is lighter, cost-effective, and suitable for lower current needs. Choose based on load requirements, environmental conditions, and budget, ensuring compliance with standards and manufacturer specifications for optimal performance.

10.3 Specialized Cables for High-Temperature Applications

Specialized cables for high-temperature applications use advanced insulation materials like silicone or Teflon, offering superior heat resistance. These cables are designed for environments exceeding standard operating temperatures, ensuring reliable performance and safety. They are ideal for industrial, automotive, and aerospace applications, where extreme heat could otherwise degrade standard cables, compromising electrical systems.

Tools and Resources for Cable Size Calculation

Utilize cable size and current rating PDF guides, online calculators, and manufacturer specifications to ensure accurate calculations. These tools provide detailed charts and formulas for precise cable selection and sizing.

11.1 Cable Size and Current Rating PDF Guides

Cable size and current rating PDF guides provide comprehensive charts, tables, and formulas for precise cable selection. They include cross-sectional areas, voltage drop calculations, and current-carrying capacities, ensuring compliance with international standards like DIN VDE and IEC. These resources are essential for engineers and electricians to ensure safe and efficient electrical installations.

11.2 Online Cable Size Calculators and Software

Online cable size calculators and software simplify the process of determining the appropriate cable size and current rating. These tools offer real-time calculations based on input parameters like power, voltage, and distance. They also provide voltage drop analysis and support for multiple conductors, ensuring accurate and efficient cable sizing for various applications.

11.3 Manufacturer Specifications and Technical Support

Manufacturer specifications provide detailed cable size and current rating charts, ensuring compliance with international standards. Technical support teams offer guidance on selecting the right cables, interpreting data, and addressing specific application needs, ensuring safe and efficient installations tailored to individual project requirements.

Leave a Reply

You must be logged in to post a comment.